XPlanar: redefining linear transport, defying the limits of engineering

- Jeff Johnson

- Feb 12, 2025

- 2 min read

Updated: Mar 12, 2025

The next evolution of linear transport technology transforms how engineers approach automation and mechatronics

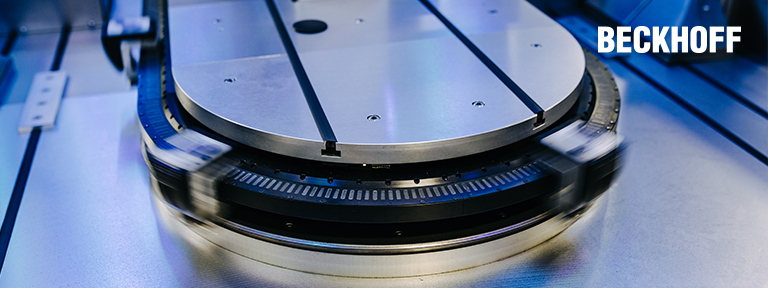

Beckhoff's XPlanar is a groundbreaking – and gravity defying – advancement in linear transport systems. It offers unprecedented flexibility and innovation for numerous industries that face complex material handling requirements. XPlanar’s capabilities empower engineers to completely rethink motion control and implement truly adaptive automation.

Through the power of magnetic levitation, XPlanar breaks through traditional material handling constraints. XPlanar uses passive movers with permanent magnets that float and fly across electromagnetic tiles, providing six degrees of freedom in motion. This means movers can move up, down, tilt, rotate, and traverse freely in X and Y directions.

What makes XPlanar the next evolution of linear transport?

The system offers significant advantages including:

Minimized machine footprint

Increased productivity

Shortened time-to-market

Lot size 1 production, maximum product mix flexibility

Application and industry specific advantages

Technological innovations and recent developments

Beckhoff's XPlanar advances include a new 320x320 square tile format, stainless steel movers, 127-millimeter movers, upcoming rectangular movers, and multi-PC control for larger systems. These innovations enhance flexibility, performance, and scalability across diverse manufacturing applications, demonstrating the technology's continuous evolution.

Programming and Customization

XPlanar offers flexible programming through TwinCAT software, allowing path-based development and precise coordinate management. The system supports graphical and code-based programming approaches. Beckhoff continues to expand XPlanar's capabilities, focusing on increased modularity, broader track layouts, and full six-degree-of-freedom motion.

A diverse range of industry applications

The webinar showcased multiple innovative applications across diverse sectors:

Manufacturing and Assembly

In Beckhoff's own manufacturing facility, XPlanar manages the production of over 4,000 IO terminals. The system demonstrates "lot size one" capabilities, allowing different terminals to be processed simultaneously with maximum flexibility.

Food Processing

Leading food processing equipment manufacturer Provisur utilized XPlanar for cheese slicing and buffering systems. The technology reduced machine footprint by creating efficient multi-lane buffering, enabling continuous production during product changeovers.

Lab Automation

XPlanar revolutionizes lab processes by eliminating traditional conveyor systems and robotic transfers. The system can directly access processing cells, synchronize liquid handling, and optimize spatial utilization.

Plasma Treatment

By replacing multiple six-axis robots, XPlanar provides precise substrate positioning and coating, reducing equipment complexity and footprint.

A seamless integration experience for Automation Nth

Joe Caccini from Automation Nth shared his own integration experience with XPlanar, highlighting Beckhoff's comprehensive support. The company provided extensive testing, simulation tools, and personalized guidance, making implementation smoother and faster.

The paradigm shift you never saw coming

XPlanar represents more than just a transportation technology—it's a paradigm shift in how manufacturers conceptualize motion control and automated process design. By providing unprecedented flexibility, reducing complexity, and enabling sophisticated motion profiles, XPlanar is already transforming automation in numerous applications in the field, encompassing many industries. The technology's contactless, clean, and quiet operation makes it adaptable to various industrial environments, from complex manufacturing settings to high-precision laboratories.

Ready to take the next step in linear transport technology with XPlanar? Contact your local Beckhoff sales engineer today.

And don't forget to check out our upcoming and on-demand webinars to stay current on the latest automation innovations from Beckhoff.

Jeff Johnson is a Mechatronics Product Manager at Beckhoff Automation LLC

Comments