High-Speed, High-Mix Production Made Easy with XTS

- Jeff Johnson

- Nov 5, 2025

- 2 min read

Transforming Motion Systems for Modern Manufacturing

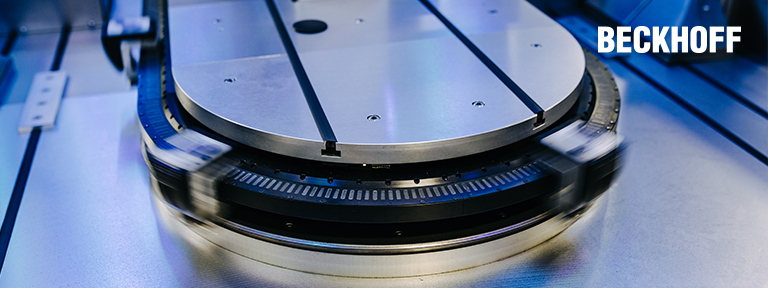

In today’s manufacturing landscape, speed, flexibility, and efficiency are more critical than ever. Jeff Johnson, Mechatronics Product Manager at Beckhoff USA, highlights how the XTS linear transport system addresses these demands. He explains that XTS combines the continuous motion of rotary motors with the precision and flexibility of linear motors, enabling independent mover control along complex paths.

Traditional indexing systems have limitations: fixed pitch, speed, direction, and synchronous motion constrains productivity and flexibility. XTS overcomes these challenges through asynchronous motion, where each mover operates independently. This allows multiple “up” stations, buffering between stations, and smooth handling of varying product sizes without slowing the entire process. Manufacturers can now consolidate multiple machines into one flexible system, significantly reducing footprint and complexity.

Download the full webinar recording from the form below:

Key Advantages in Real-World Applications

XTS excels in high-mix production environments. In a pharmaceutical L-shaped track, the system handled stations with differing capacities, single, two, three, and five-up, demonstrating unmatched adaptability. Similarly, in consumer packaging, the XTS allows rapid format changes, switching from single stacks to sleeves of cookies through software-controlled motion instead of mechanical adjustments. This reduces setup times from hours to minutes.

Maintenance is simplified with two rail options. Beckhoff’s plastic-roller guide rails support light payloads with low wear, while the robust HEPCO rails carry heavier loads and include self-cleaning features for dusty or hygienic environments. Both options minimize mechanical wear and extend system longevity.

Innovation Meets Flexibility

XTS supports dynamic track layouts, automatic mover pitch adjustment, and on-the-fly product handling. High-mix production benefits from software-based changeovers, rapid prototyping, and integrated robot synchronization. Eco-line motor modules offer cost savings for non-critical sections, while standard modules maintain precision where needed. This combination maximizes performance while optimizing cost and footprint.

Hygienic applications also benefit. XTS offers IP69K-rated solutions for washdown and chemical resistance, ensuring compliance in food, beverage, and pharmaceutical industries. Extensive testing confirms that the system maintains cleanliness and reliability even under harsh conditions.

Driving the Next Generation of Machines

By integrating motion, HMI, and IoT into a single controller, XTS simplifies machine design, accelerates development timelines, and allows manufacturers to innovate faster. From high-speed capping to multi-product packaging, XTS delivers flexibility, reliability, and efficiency, helping companies stay competitive in an increasingly demanding market.

Discover how XTS can make your production faster, more flexible, and more efficient. Contact your local Beckhoff sales engineer today.

And check out our upcoming and on-demand webinars to stay current on the latest automation innovations from Beckhoff.

Jeff Johnson is a Mechatronics Product Manager at Beckhoff Automation LLC

Comments