The Path to Cabinet-free Automation is Clear with the MX-System

- Brandon Snell

- Jul 17

- 6 min read

Updated: Sep 9

The culmination of over 45 years of Beckhoff’s New Automation Technology has brought us to a pivotal turning point in the history of controls technology. The question is, will you take advantage of it?

The industrial automation landscape is undergoing a fundamental shift right now. As global manufacturers face increasing pressure to reduce costs, keep facilities moving despite protracted skilled labor shortages, and accelerate time to market, the traditional approach to automation and machine control—with bulky control cabinet enclosures and extensive field wiring—is increasingly a liability. Beckhoff’s MX-System offers a breakthrough roadmap for this seemingly unsolvable dilemma. With over four decades of automation innovation, Beckhoff is releasing a complete cabinet-free automation platform that transforms how engineers think about control architectures, machine design, and factory floors.

Beckhoff has long set the pace in the industry as a pioneer in automation technology and never settled on the ways things have always been done. From pioneering PC-based control and EtherCAT technologies to field-tested innovations in I/O, motion control, mechatronics, and beyond, Beckhoff’s deep and ever evolving portfolio reflects a commitment to performance, openness, and adaptability. The MX-System is the next natural progression in this never-ending journey—leveraging decades of hard-earned expertise to break down the constraining walls of the pervasive control cabinet.

A methodical march toward cabinet-free automation

Of course, Beckhoff didn’t arrive at the MX-System overnight. We have steadily moved automation and controls components out of a central cabinet to shorten the distance to the end device or process:

Fieldbus Box and EtherCAT Box made IP67- and IP69K-rated distributed I/O a practical reality to get machine mountable I/O closer to sensors, actuators, motors, and more.

AMP8000 Distributed Servo Drives combined a servo drive and servomotor into one compact, IP65-rated, machine mounted device. This further minimized control cabinet requirements and cable runs. Cabinet-free modules for distributed power supply and decentralized drive distribution further increased the space savings.

C7015 ultra-compact Industrial PCs provided rugged, machine-mountable PC-based control outside of electrical cabinets.

These steps weren’t isolated innovations or mere strokes of luck, they were intentional building blocks toward something greater. And now, with the MX-System, Beckhoff completes this phase of the journey by offering the world’s first fully integrated, cabinet-free automation platform.

So what is the MX-System?

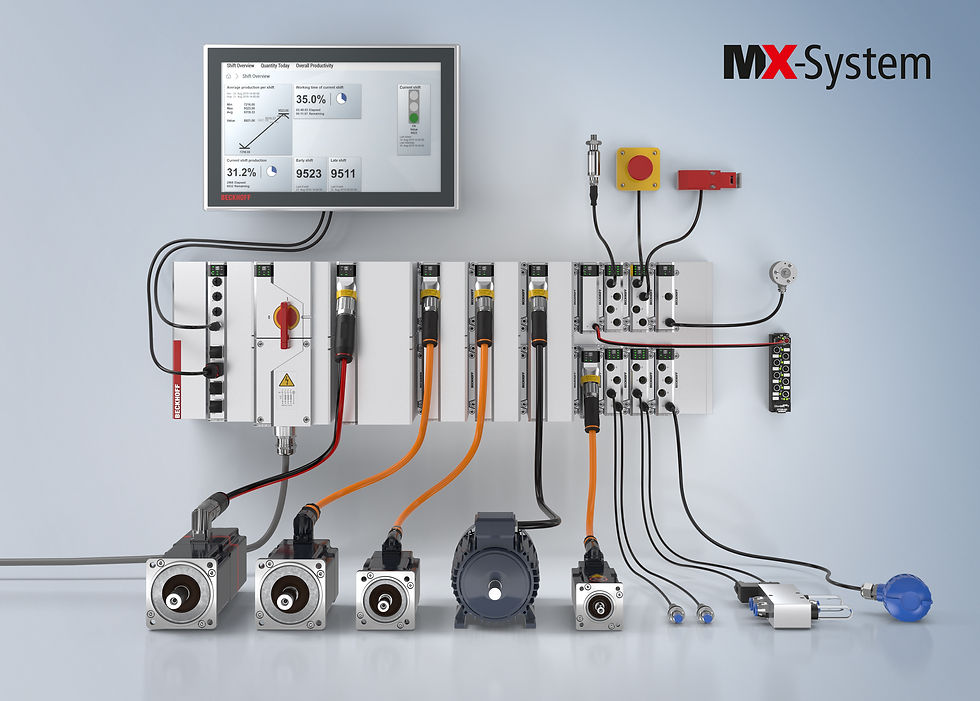

At its core, the MX-System is a modular, IP67-rated control hardware platform. Via machine mounted baseplates and pluggable modules, the MX-System combines power distribution, PC-based automation, drive technology, I/O, safety, and more into a unified platform that installs directly on the machine—no cabinet required.

With the MX-System, machine builders can choose between the new cabinet-free alternative to automation, traditional in-cabinet control or a hybrid approach. It integrates seamlessly with Beckhoff’s existing range of hardware and software technologies via EtherCAT industrial Ethernet and standard TwinCAT automation software. In terms of programming and networking, there’s almost no learning curve for engineers already familiar with the Beckhoff ecosystem.

The result? Unmatched flexibility, modularity, and simplification across the entire machine lifecycle—from design and assembly to installation, commissioning, and maintenance.

Where can the MX-System make a practical difference for you?

For OEMs: Efficiency, speed, and scalability

Machine builder OEMs face intense pressure to innovate rapidly while managing cost, risk, and tight delivery timelines. The MX-System gives OEMs a toolset to check all those boxes and secure an early lead on a major competitive advantage. By eliminating traditional control panels and enclosures, OEMs can dramatically reduce:

Panel building and wiring time

Sources of error

Cooling requirements

Power distribution complexity

Certification and compliance efforts

With modular, pluggable components and cables with simple connectors, the MX-System reduces dependence on panel vendors and shortens lead times which is critical considering continued supply chain volatility. OEMs can expect up to a 75% reduction in required parts and electrical documentation. MX-System also enables OEMs to deliver machines with consistent, scalable architectures that support easy maintenance and future expansions.

Most importantly, the MX-System supports a functionally modular machine design approach, where each machine segment includes standardized, testable control units. This design philosophy dramatically accelerates the build process and simplifies field service and support.

For system integrators: Simplified commissioning, faster project completion

System integrators (SIs) are often the bridge between the OEM’s machinery and the factory floor needs of end users. The MX-System empowers SIs to streamline their workflows, reduce engineering hours, and finalize projects faster. With no control cabinet to install, wire, or cool, integrators can focus on the value-added tasks their clients depend on most—like fine tuning of the process at hand, integration with other factory equipment, and data integration.

Modular design also helps SIs maintain consistent system architectures across projects, improving reliability and predictability. The plug-and-play nature of the MX-System enables faster installations and commissioning, even in complex or space-constrained environments. MX-System reduces the need for highly skilled electricians for commissioning. Cabinet-free automation can reduce required installation and wiring labor by up to 95%.

For end users: Space savings, performance, and uptime

End users face daily pressure to keep operations running efficiently and cost-effectively. For them, the MX-System offers:

Space efficiency with compact, cabinet-free machine design

Improved uptime with error-free, plug-and-play components

Faster troubleshooting and maintenance via real-time diagnostics and standardized connections

Energy savings through the elimination of power-hungry cooling equipment

For facilities facing space and mobility constraints, the compact, IP67-rated MX-System removes the need for bulky enclosures, freeing up valuable floor space and allowing for more flexible machine layouts. End users can expect to reduce overall control system footprint by 90%. All automation equipment can be mounted directly on the machine—even in wet or dirty plant environments. Decentralized installation enables greater mobility and accessibility, improving operational efficiency.

With built-in energy management, the MX-System actively monitors and optimizes power consumption, helping end users lower energy costs while maintaining peak performance. By offering a fully integrated, modular automation platform, the MX-System simplifies system expansion and provides a future-proof solution for modern manufacturing environments.

What industries stand to gain the most?

The MX-System’s versatility makes it suitable for a vast range of industries and can impact countless application areas, but here are four industries to highlight:

Automotive

In the ultra-competitive world of automotive manufacturing, every process optimization and cost saving measure can make all the difference. And it’s a widely shared belief that the toughest part of the industry isn’t in vehicle design, it’s in production. The MX-System changes the game with:

Space savings in crowded assembly and production lines

Rapid deployment of modular machines

Consistent system design that meets local power requirements for global networks of manufacturing facilities

Digital Manufacturing

Smart factories demand smart infrastructure. Whether deployed in additive manufacturing, fabrication, machine tools, or woodworking, the MX-System provides ample support with:

A smaller footprint for job shops of all sizes

Scalable modules for rapid reconfiguration to accommodate 3D prototyping

Future-ready design for applications that are quickly evolving

Intralogistics

With widely distributed applications and high demands for scalability and speed in bustling e-comm and distribution centers, intralogistics is a natural fit for the EtherCAT-enabled MX-System. Benefits include:

Elimination of third-party panel building, no outsourcing required

Easy modular expansion of conveyor and sortation systems

Reduced cost and complexity in high-speed, widely distributed applications

Packaging

In packaging, where margins are low and uptime is critical, the MX-System delivers:

Improved diagnostics and reduced downtime

Streamlined commissioning and shorter time-to-market

Relief from skilled labor shortages through simplified system design and easier maintenance

Compact machine footprint, ideal for holding plant expansions at bay

So what’s next? More power, modularity, and future expansions

Think of the MX-System as more than just an automation platform; it’s a reset on the electrical aspects of machine design. However, it’s also remarkably compatible with the automation technologies that preceded it. It’s “plug and play” in more ways than one. Beckhoff is already expanding the MX-System’s capabilities to support higher power inputs and a continuously expanding range of function modules, enabling cabinet-free automation for even more use cases.

Whether you’re going fully cabinet-free or building a hybrid solution, the MX-System offers the perfect jumping on point, and the flexibility to grow with your needs.

A modular automation platform for a modular world

The MX-System represents a multilayered paradigm shift. It’s not just about eliminating control cabinets—though it does that exceptionally well as its most immediate and noticeable impact. MX-System is also about encouraging a more modular, efficient, and forward-thinking approach for a new era of machine design.

So how will the engineers of the world respond? By encapsulating all aspects of automation and controls functionality into standardized, testable modules, engineers gain the power to build machines that are faster to develop, easier to maintain, and more adaptable to unforeseen future needs. From OEMs and system integrators to end users across industries, the MX-System delivers powerful benefits that solve age-old problems that previously hadn’t been met by modern automation technology.

Cabinet-free automation isn’t just an exciting possibility—it’s the optimal path forward in today’s landscape of available controls technologies. With the MX-System, Beckhoff has cleared that path and made it more attainable than ever. Ultimately, what’s next is up to you—which direction will you take?

Are you ready to completely transform your machines and facilities with the MX-System and gain an unmatched competitive edge? Connect with your local Beckhoff sales engineer today and join the cabinet-free revolution with us.

Brandon Snell is the MX-System Product Manager at Beckhoff Automation LLC.

Comments