Rewrite the rules of industrial automation with a cabinet-free approach: the MX-System

- Brandon Snell

- May 7, 2025

- 3 min read

Updated: Sep 9, 2025

Imagine eliminating bulky control cabinets, slashing installation time, and shrinking your machine footprint—without sacrificing power or performance.

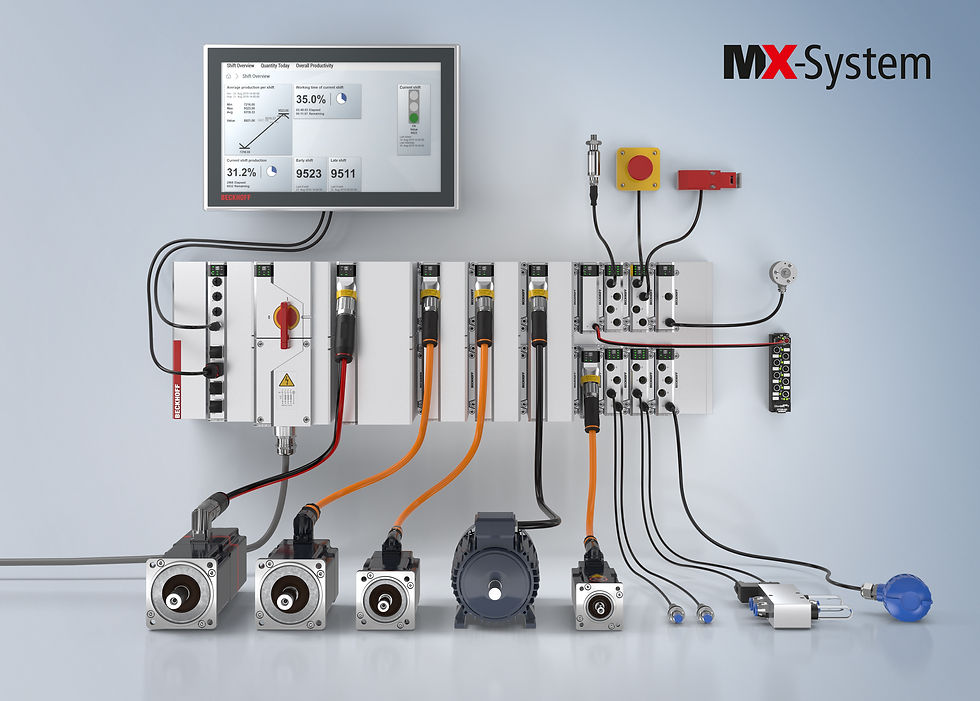

In a recent edition of Beckhoff USA's Webinar Wednesday, Product Manager Brandon Snell introduced the game-changing MX-System, a highly modular, cabinet-free control platform designed to simplify machine design and transform industrial automation forever. The webinar provided insights into how the MX-System reimagines traditional control cabinets and paves the way for smarter, more efficient machines.

The motivation: breaking free from the cabinet for good

From the advent of steam-powered machinery to modern IoT-connected automated systems, we’ve seen the transition from one industrial revolution to the next. While programmable logic controllers (PLCs) and traditional control cabinets marked a significant advancement in the 60s and 70s, the physical design of automation systems has remained largely unchanged since. Control cabinets still dominate, bringing with them complex wiring, significant spatial demands, high energy consumption, and cooling challenges. As manufacturing continues to push toward more compact and modular machinery, the industry is ripe for disruption — and that's where the MX-System changes everything.

Introducing the MX-System!

The MX-System is Beckhoff's answer to the age-old limitations of traditional control cabinets. At its core, it's an exceptionally modular, fully EtherCAT-based platform that integrates all the functionalities found in a standard control cabinet into a scalable, machine mountable system with IP67 protection. This approach dramatically reduces the footprint (up to 90%) and weight (up to 60%) of conventional automation system setups.

This webinar highlights the MX-System's literal foundation: the baseplates, which replace traditional wiring by providing data and power distribution. The data board handles low-voltage communication (EtherCAT), while the power board manages high-voltage power (up to 848V DC or 480V AC). These baseplates also feature onboard diagnostics to monitor temperature, vibration, dew point, and more — adding intelligence to what would otherwise be passive hardware.

Rugged, smart components

The pluggable MX-System modules feature robust IP65/IP67-rated housings, enabling use directly on the machine — even in damp, dusty, and corrosive environments. The components are passivated and coated to prevent corrosion, and their aluminum construction allows for efficient passive cooling, eliminating the need for dedicated cabinet climate control.

Scalability is king

One of the system's biggest advantages is flexibility and versatility. It can function as a decentralized power and data hub or coexist with legacy control cabinets, acting as a distributed extension with only a few key connections needed. Here are a few key use cases:

Compact test benches or simple machines: using single-row base plates with basic I/O and compact drives.

Mid-range applications: such as packaging machines, benefit from integrated motion and safety in a two-row configuration.

Complex systems: such as machine tools, use three-row plates for high current needs and seamless integration with Beckhoff's existing IP67-rated EP boxes.

A modular future

Even the system’s name “MX" stands for Modular and eXpandable, amplifying just some of the main benefits you’ll get. The system is designed to scale along with machine complexity while simplifying engineering, wiring, and maintenance. Whether you're designing a small machine and want to make it smaller or conserving valuable real estate in a factory-scale system, the MX-System offers a streamlined, intelligent alternative to bulky cabinets.

As automation demands evolve, Beckhoff's MX-System represents a forward-looking platform that’s ready to meet the needs of next-generation manufacturing. Request the full video webinar to get more information!

Ready to see how cabinet-free automation can transform your business? Contact your local Beckhoff sales engineer today.

And don't forget to check out our upcoming and on-demand webinars to stay current on the latest automation innovations from Beckhoff!

Brandon Snell, MBA, P.E. is the MX-System Product Manager at Beckhoff Automation LLC

Comments