Boost Your Integration Intelligence: The MX-System Advantage for System Integrators

- Brandon Snell

- Jul 24, 2025

- 3 min read

Updated: Sep 9, 2025

How cabinet-free automation accelerates system integration and profitability

As the linchpin in the success of many automation projects, system integrators (SIs) work at the critical intersection of machine performance and production goals. SIs are literally the ones who bring everything together, ensuring that machines not only function but thrive on the factory floor. That’s a tall order when faced with tight machine delivery and installation timelines, evolving automation technologies, and increasing demands for customizations and plant-wide connectivity.

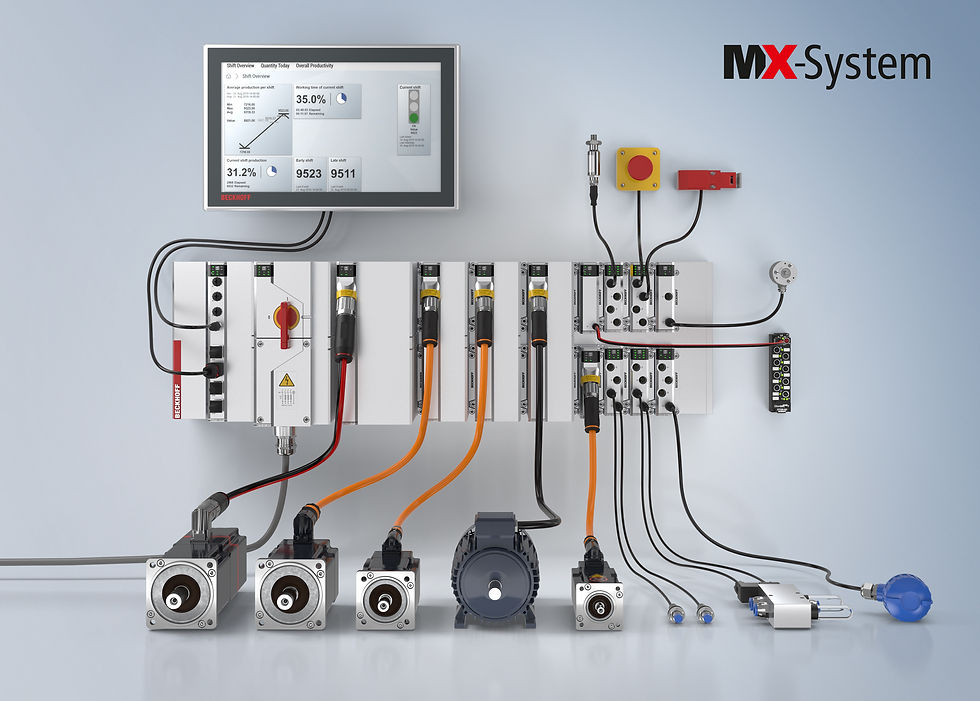

Enter Beckhoff’s MX-System, our modular, cabinet-free automation platform that gives SIs a powerful path to simplify commissioning, improve reliability, and dramatically reduce labor costs. If you’ve ever spent several hours or even days waiting on enclosure fabrication, troubleshooting messy panel wiring, or squeezing control hardware into tight, unforgiving installation spaces, the MX-System is about to change your world.

Cabinet-free means clutter-free and stress-free

Let’s start with the most obvious MX-System benefit: No more control cabinets! Traditional cabinet-based automation systems are labor-intensive, require specialized skills to install and wire, and often create headaches when changes are needed late in the project. With the IP67-rated MX-System, control components can be mounted directly on the machine frame or skid via a robust baseplate—no enclosure, no internal wiring, no cooling equipment, and virtually no downtime due to heat, moisture, or dust.

For SIs, this translates to fewer bottlenecks and a much smoother installation experience. A panel-free machine means fewer parts to track, fewer electrical drawings to revise, and far fewer points of failure. You can commission faster and deliver clean, professional installations every time, even in the most space-constrained environments. It will also lead to less stressed clients who won’t have to wait nearly as long to get production up and running.

A standard system architecture for every project

Let’s face it: No one likes reinventing the wheel, especially engineers. With the MX-System, system integrators can reuse a standardized control architecture across multiple projects for all clients—whether you’re working with the same machine builder OEM, retrofitting an older machine in a brownfield facility, or rolling out several new systems at multiple sites for a large end user.

Each MX-System installation uses the same user-friendly form factor, modular installation approach, and error-free connection principles, which lead to:

Faster commissioning and startup

More consistent and concise documentation

Simplified maintenance and service for the end user

A shorter learning curve for your team and the end user’s

In effect, the MX-System lets you build a modular integration toolkit that you can apply to almost any automation project.

Fewer specialists needed—especially for the boring stuff

Commissioning with traditional cabinets often requires highly skilled electricians—people who are increasingly hard to find and expensive to keep. By eliminating laborious custom wiring and offering pre-certified hardware and integrated Bluetooth-enabled diagnostics via a smartphone app, the MX-System lowers the SI’s threshold for specialized labor without compromising reliability or quality to the end user. This not only reduces project costs but also improves scalability. Whether you're taking on more projects simultaneously or deploying multiple systems across a large facility, the MX-System lets you build and commission with greater flexibility and handle more work at the same time.

At the end of the day, speed can make or break an SI’s reputation. The faster a machine gets online in a plant, the faster your client can start generating ROI on your project—and the more likely they are to come back to you for the next big project. As the MX-System reduces installation requirements, wiring labor, certification steps, and commissioning hours, it can significantly shorten your project timelines. That helps you meet the most aggressive schedules without burning out your team or cutting corners that may come back to haunt you.

This speed and flexibility also give you more room to focus on the custom integration work your clients value most, like setting up digital twins for machines, integrating with quality assurance systems, or developing groundbreaking adaptive manufacturing processes.

MX-System: The integrator’s edge

As leading factories chase Industry 4.0 and beyond, the need for smart, connected automation grows— as does the need for SIs who can make it all happen. The EtherCAT-enabled MX-System is fully compatible with the Beckhoff product portfolio. This gives SIs access to real-time communication, advanced diagnostics, and seamless integration with Beckhoff’s broader automation and software ecosystem.

In short, the MX-System isn’t just a major time-saver for SIs—it’s the automation platform for the future. For system integrators juggling complexity, deadlines, and resource constraints, the MX-System offers a new path forward. By removing the control cabinet from the equation and embracing a truly modular automation design, you can simplify commissioning, reduce costs, and deliver better results for your clients—faster. Whether you’re deploying machines across a facility or supporting OEMs with scalable solutions, the MX-System gives you the edge to do more with less.

Ready to supercharge your system integration efforts with the engineering efficiencies and cost savings of cabinet-free automation? Reach out to your local Beckhoff sales engineer to get started with the MX-System today.

Brandon Snell is the MX-System Product Manager at Beckhoff Automation

Comments