Make Cabinet-free Automation Your Machine Builder Advantage

- Brandon Snell

- Jul 21, 2025

- 4 min read

Updated: Sep 9, 2025

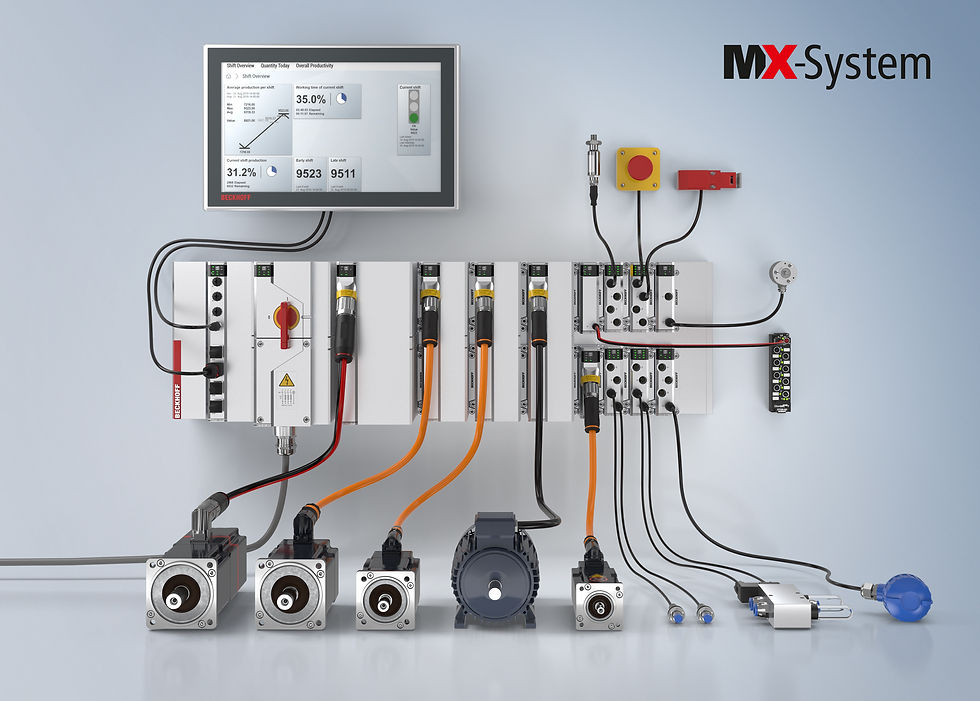

How the MX-System empowers OEMs to build smarter, faster, and leaner machines

In today's high-stakes manufacturing landscape, machine builder OEMs are under more pressure than ever to maximize revenue with shrinking resources and an increasingly uncertain macroeconomic climate. The demand for shorter delivery times, more flexible machine control architectures, and reduced costs—without compromising innovation or performance—can feel like a constant juggling act. But what if one change to your control system architecture could tip the balance in your favor?

Enter the MX-System from Beckhoff, the game-changing, cabinet-free automation hardware platform that’s redefining what's possible for OEMs around the world. This transformative technology is emerging now, so the OEMs who capitalize on it first will lock in a formidable competitive advantage.

Kick the control cabinet to the curb

Traditional control cabinets are notorious for being time-consuming, costly, and cumbersome. They require extensive hand wiring, energy-intensive cooling, and significant documentation for every machine. But these are no longer facts of engineering life. The MX-System flips the legacy approach on its head with something that’s entirely new on one hand, and a planned series of technological developments on the other.

By fully eliminating the need for control cabinets, the MX-System simplifies every phase of the machine development lifecycle—from design and engineering to build, testing, commissioning, and field service. This allows OEMs to focus on enhancing and delivering end user value, not chasing long cable runs, wiring errors, and compliance.

The result? A dramatic reduction in build and wiring time, elimination of sources of error, and significantly reduced space and cooling requirements. And because the MX-System uses modular, IP67-rated components, all automation hardware can be directly mounted on the machine frame—without any external protective enclosure.

OEMs have to innovate to differentiate

In today’s hyper-competitive industrial landscape, OEMs are under constant pressure to innovate: keeping up in the chase toward the latest technology advancements, faster design cycles, smarter machines, and tighter margins are the new normal.

Yet, as competing machines crowd the market and commoditize core technologies, real differentiation becomes harder for machine builders to achieve. Our MX-System offers OEMs a powerful way to break through these barriers with something new. The MX-System enables faster builds, reduced engineering complexity, and scalable machine designs that stand out in ways that just can’t be matched by a competing platform yet. It transforms how automation and control systems are housed and installed from a constraint into an undeniable competitive advantage.

This allows OEMs to focus on what truly drives market value: performance, reliability, flexibility, and rapid time to market. With the MX-System, innovation is no longer muddled by electrical cabinets or outdated design practices that add no value—differentiation is built in from the start.

Mitigating supply chain risks and documentation overload

Considering today’s uncertain supply chain, delays in sourcing control panel components can throw entire production schedules off track. The MX-System reduces the risk by streamlining hardware selection and removing reliance on third-party panel builders.

Because the system’s modules and power supplies connect via standardized pluggable cables, the number of unique control system parts can be reduced by up to 75%, along with a proportional reduction in electrical documentation. That means fewer part numbers to track, fewer schematics to generate, and fewer opportunities for mistakes. This standardization not only simplifies engineering workflows but also makes it easier to build machines at scale, replicate installations globally, and quickly onboard and train new team members.

Scale machines for the long haul

Beyond the mechanical and electrical advantages, the MX-System enables a shift in how machines are designed—toward functionally modular machine architectures. In this approach, each segment of the machine contains its own standardized, testable control unit. These segments can be assembled in parallel, validated independently, and combined quickly to form the complete machine.

This not only accelerates the build process but also transforms machine support in the field. Service technicians can isolate and replace control modules without needing to dive into a complex cabinet or interpret tangled wiring diagrams. The result is faster diagnostics, quicker replacements, shorter downtime, and happier end customers.

Machine builders don’t just need to deliver systems that work today, they need solutions that can evolve and grow with ongoing automation technology advancements. The MX-System supports future expansions and retrofits by making it easy to add modules or reconfigure the control setup without re-engineering the entire machine. And because all MX-System modules communicate via EtherCAT, OEMs can scale their control architecture based on machine size, complexity, or customer needs—without having to reinvent the wheel every time.

This is the competitive edge you’ve been waiting for

For OEMs navigating today’s challenges, the Beckhoff MX-System offers more than just a new control hardware platform—it represents a transformational shift in how machines are built, supported, and scaled. By eliminating control cabinets, slashing complexity, and enabling functionally modular design, the MX-System gives OEMs all the tools they need to innovate faster, reduce complexity, and deliver smarter machines to market.

Are you an OEM who's ready to take the leap ahead of the machine builder competition with cabinet-free automation? Reach out to your local Beckhoff sales engineer to get started with the MX-System today.

Brandon Snell is the MX-System Product Manager at Beckhoff Automation

Comments