Additive Manufacturing: Secure a Leading Edge in the Industry

- Paxton Shantz

- Aug 13, 2025

- 2 min read

Updated: Sep 9, 2025

Unlock the full potential of additive manufacturing with scalable automation solutions in this edition of Webinar Wednesdays.

Additive manufacturing (AM) is transforming how industrial equipment is built—from prototyping to full-scale production. In our recent Webinar Wednesday session, we explored how automation technology can help companies stay ahead in this fast-moving industry. This webinar spotlighted the growing role of open, flexible, and scalable automation systems in building smarter, more efficient additive machines.

Download the full recorded webinar here:

Why flexibility is critical in additive manufacturing

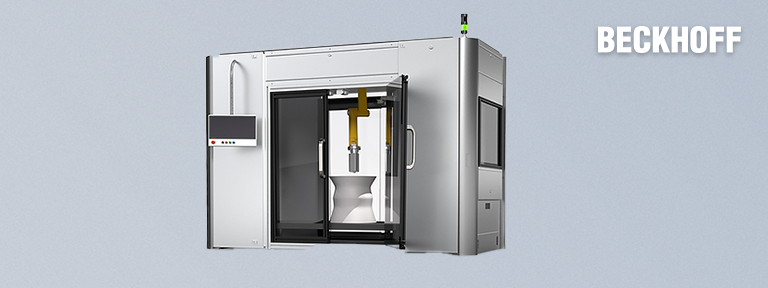

Especially in additive manufacturing applications, flexibility is key, and systems must adapt to rapidly evolving materials, product requirements, and innovation cycles. Whether working with metal, photopolymer, or hybrid processes, machine builders need technology that enables quick pivots and tight integration to remain competitive. Beckhoff’s modular, PC-based control platform provides that adaptability—with support for precise motion, environmental control, and advanced connectivity all in one software environment.

Unified control drives performance

Instead of relying on multiple control platforms, Beckhoff consolidates motion, safety, measurement, and more onto a single PC-based system using TwinCAT software and EtherCAT communication. This unified approach allows for better synchronization between machine functions, reduces hardware complexity, and boosts throughput—essential for demanding AM processes like laser sintering or resin curing.

Real-world results in AM applications

Throughout the webinar, we shared practical examples of how our solutions are powering real additive systems transforming the industry today. From complex multi-axis gantries to tightly controlled thermal zones, Beckhoff’s high-speed EtherCAT I/O and deterministic communication enable engineers to build with precision and scale production efficiently. System integrators and OEMs alike benefit from simplified engineering and faster commissioning.

Open automation means future-proof machines

In today’s hyper-connected world, AM machines must easily link with MES, ERP, and cloud platforms. Beckhoff’s open architecture—supporting standard IT protocols, common programming languages, and flexible I/O options—makes this possible. Whether you’re feeding real-time data to analytics tools or implementing predictive maintenance, you gain more control and visibility into your processes.

Powering next-generation additive systems

From motion control and machine vision to temperature regulation and feedback, Beckhoff’s fully integrated systems are built to meet the exacting needs of modern manufacturing. With controls support for multi-core processors, machine learning, and true real-time responsiveness, our platform helps additive equipment manufacturers push the boundaries of what’s possible.

The road ahead for AM

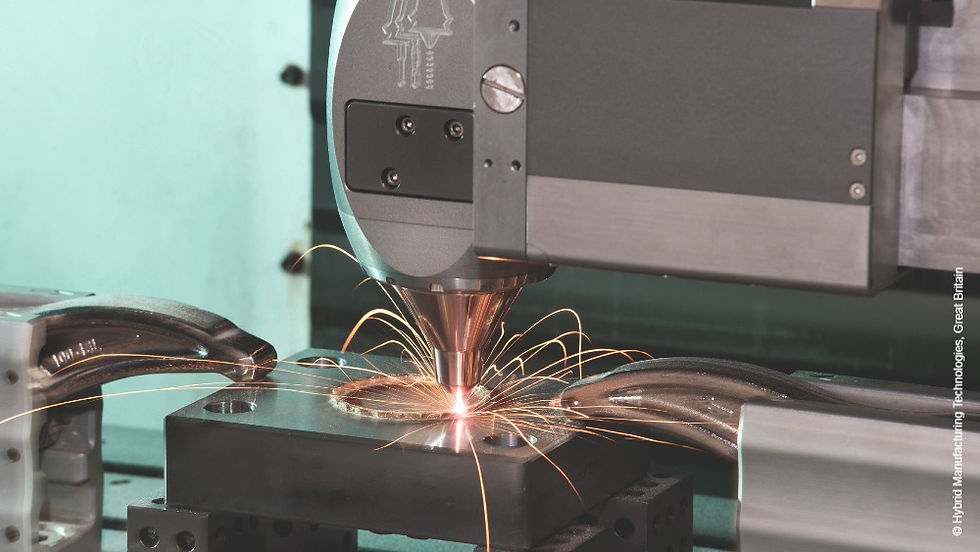

As the additive industry evolves, manufacturers are increasingly blending subtractive and additive processes together, emphasizing quality assurance, and delivering customized products at scale. Beckhoff is ready to support this evolution with automation solutions that scale from prototype development to global production lines—without needing a complete system overhaul.

Bring innovation to life with Beckhoff

Whether you're developing a cutting-edge 3D printer or optimizing high-throughput additive manufacturing, Beckhoff’s modular automation technology offers the tools to move faster, integrate smarter, and build better.

Ready to take your additive manufacturing systems to the next level? Contact your local Beckhoff sales engineer today!

And don't forget to check out our upcoming and on-demand webinars to stay current on the latest automation innovations from Beckhoff!

Paxton Shantz is a Digital Manufacturing Industry Manager at Beckhoff Automation LLC

Comments