What Is the XPlanar System?

- Jeff Johnson

- Mar 8, 2021

- 3 min read

Updated: Jul 19, 2023

The new Flying Motion solution from Beckhoff addresses key trends in automation and control

Today’s machine builders and manufacturers need new solutions to boost throughput and uptime while enabling greater customization. Consumer demands for more personalized and seasonal products, down to lot size 1, are driving this trend. However, this requires additional tooling, processing stations and a wide variety of packaging options in terms of sizes, types and graphic design. In a traditional inline setup, either the product would have to pass every processing station, including many that are not required for that custom product, or operators would have to perform constant changeovers to swap out different tools. The XPlanar system from Beckhoff is ideal for these complex production and material handling applications.

Consider the traditional approach vs. XPlanar with shampoo, for example: A brand might offer dozens of optional scents and additives that consumers can choose from online in the size they want. Maybe someone only wants a small bottle with tea tree oil, but another person wants a large bottle with lavender, coconut and specific vitamins. In the inline process, the bottle would have to pass every filling station, and an operator would have to adjust the machine for smaller or larger bottles. With XPlanar, multiple bottle sizes can be processed at once. The system’s built-in path planning and collision avoidance algorithms ensure that the bottle gets to only the needed filling stations as quickly as possible. That’s just one example, among many similar use cases. XPlanar delivers unprecedented flexibility while increasing throughput.

Technology benefits and unique advantages of XPlanar

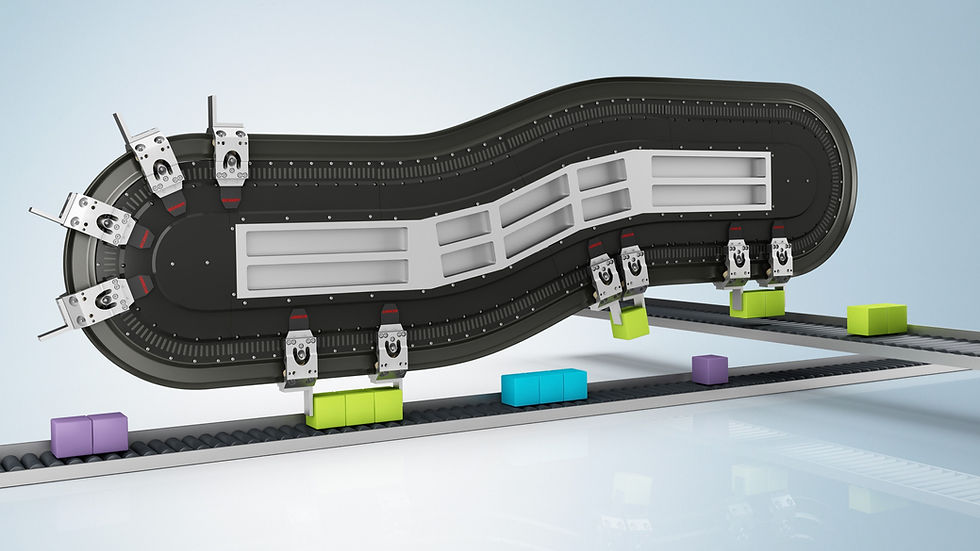

XPlanar consists of planar motor tiles and passive planar movers that levitate magnetically and move with six degrees of motion: X, Y, Z (lift), rotate and tilt in X and Y. The planar motor tiles can be arranged in any configuration, which enables flexible track layouts for free and dynamic movement. As such, the system can offer multiple lanes and parking spaces while easily diverting rejects. Rather than a standard linear transport system or conveyor, XPlanar offers multiple tracks on the same surface from infeed to outfeed.

The system provides built-in collision avoidance, path planning, anti-slosh capabilities for transporting liquids and other sensitive products. This intelligent transport system from Beckhoff allows machines to adapt and react on the fly no matter what is happening in the process.

Ideal vertical markets and applications for flying motion

XPlanar is adaptable to tough environmental conditions, such as those found in cleanrooms, washdown areas, vacuums, etc. The planar motor tiles can be covered with glass, stainless steel or other materials to suit the specific application. The levitating and flying movers create no wear, which eliminates contamination that is common with conveyors, belts and other standard material handling components. These advantages make the mechatronic solution ideal for pharmaceuticals, scientific research or lab automation, food and beverage, as well as assembly, packaging and other demanding industries. It supports a variety of current design concepts and production layouts, but also enables exciting new ones, such as the processing bridge that sets up batches of movers for filling, capping, assembly, inspection and buffering.

Solving challenges for design and system engineers

XPlanar allows engineers to fundamentally rethink machine designs and replace outdated systems. As with the eXtended Transport System (XTS) from Beckhoff, it is important to build machines around the features and benefits of the system. The planar motor system can do much more than simply replace conveyor technologies, and it needs to in order to make sense from a cost perspective.

To achieve unprecedented flexibility and throughput, engineers must implement this new technology with intention and strategic consideration. As a system that immediately boosts competitiveness, XPlanar can reduce floor space, support modular production concepts and combine multiple machines into one.

Want to learn more about mechatronics can boost industrial automation applications? Visit our webpage on XPlanar or contact your local Beckhoff sales engineer today.

Jeff Johnson is the Mechatronics Product Manager for Beckhoff Automation USA.

Comments